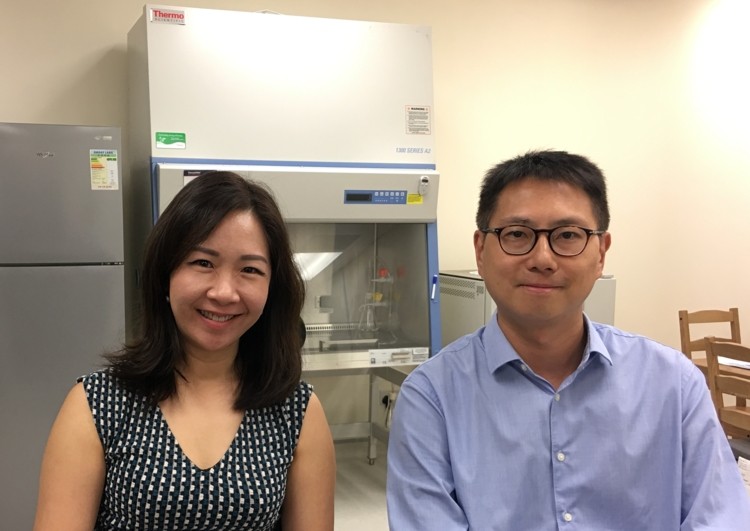

EMPEA interviewed Carrie Chan, Co-Founder, and CEO of Avant Meats, an alt protein startup using cellular agriculture to grow premium fish, in addition to beef and other animal proteins. Founded in 2018 and based in Hong Kong, Avant Meats has raised early funding from a range of global investors, including China Venture Capital, AngelHub, ParticleX, Lever VC, CPT Capital, Loyal VC, Artesian, 208 Seed Ventures, PTG Food, Markus Haefeli of responsible tilapia producer Regal Springs, and Vietnam-based Vinh Hoan, one of the largest global exporters of fish.

EMPEA: Avant Meats has raised pre-seed and seed funding from a mix of investors before and during COVID-19. How was the fundraising process?

Carrie Chan: We started our R&D in early 2019 and raised a small pre-seed round in mid-2019 from VCs including Lever VC, a global alt protein-focused fund, CPT Capital. a family office from the UK, and Loyal VC from Toronto, started by two alumni from INSEAD, where I graduated with my MBA. We went on to do further fundraising in early 2020 and closed with a mix of institutional investors, angels, and mission-driven investors.

We are based in Hong Kong, which is a hub for a lot of financial activity, but not so much for VC. So we are fortunate to have an international investor base that is looking at how this technology will be implemented in Asia, China, and other markets.

Fundraising slowed a bit during Covid. People couldn’t travel, conferences were not happening. But after three or four months, people were realizing that the food supply chain and issues around food security would be affected in the long run. Alternative protein went from a “good-to-have” trend for people who want to eat healthy to a turning point around May or June 2020, where we started to see people beyond this community thinking, “OK, we need to look at alternatives for the food supply chain.” So we have felt the momentum picking up since then. We ended up closing more than we had set out to raise. That was great.

Why did you venture into alt protein and how did you connect with your co-founder & CSO Mario Chin?

I’ve been a vegan for five years. I was excited about the idea that we can produce meat without the animals. I don’t need to tell people to eat less meat and just eat salad — that’s a challenging approach.

There were already a number of small players developing plant-based alt protein in Asia, including in Taiwan and China. But no one was developing cell-based meat for this high meat consumption region. Cell-based meat or cultivated meat contains the actual animal cells, thus its nutrients and flavors. It is not a vegetarian analog of meat, but simply meat made in a different way that does not involve the continuous slaughtering of animals.

I started out alone for the first six months. I was looking for a Chief Scientist and interviewed a number of candidates with our scientific advisor, Dr. Steven Kattman. He helped me assess their tech background. There was interest from different places, including Japan and China, but it turned out Dr. Chin was based in Hong Kong, so everything was quite smooth. We didn’t need to uproot. Our lab is in the Hong Kong Science Park. And we didn’t need much capex to begin.

Is producing alt protein a necessarily capital intensive process? Plant protein seems cheaper and quicker to bring to market.

Cellular agriculture is definitely capital intensive because it’s multi-disciplinary, from stem cell / tissue engineering technology, to bio-processing design, cell culture medium… the barrier of entry is very high, and that’s why we like it.

Unlike pharma, where it’s about a single solution molecule, then you do clinical trials and launch in market — with cellular agriculture we are talking about a scientific principle that has existed for a long time: growing animal cells outside of animal bodies. Only the new thing here is to scale up the same process on a large scale, at a much lower cost, and without using animal-derived raw materials other than the cell lines.

We can’t go to market as quickly as a plant-based startup or a player like NotCo in Chile. It takes two or three more years to commercialize because of R&D and the bioprocess scale-up of much higher complexity. But once we occupy the patent space, it has a longer lifetime, like pharma. So it’s an interesting combination from that perspective.

How is Avant Meats situated in the larger cellular agriculture space in terms of the tech and intended market?

The early generation, companies like Memphis Meats in the US and Mosa Meat in Europe, took care of everything from the animal biopsy and the cell line to the development medium and scale-up bioprocesses, until they reached a final product — the whole A-Z process. It involves at least four core areas of R&D and patents. Because there were no commercial solutions adapted to this new technology, this first generation had to do it all in house from the beginning. These companies are generally focused on main species like beef because, in the western menu, it’s the most expensive protein. And it makes sense to start with something more expensive, so you can reach price parity earlier. So that’s the first generation.

The second group includes companies like Avant Meats, or also Shiok Meats in Singapore, Blue Nalu in California, and Wildtype, who differentiate by animal species and geographical market focus. Some of us are still doing that whole process, but some start to focus on one or two of the enabling technologies while outsourcing others to commercial solutions. At Avant Meats, we have the full platform technology, meaning that we can develop a new meat-type end-to-end, from scratch all the way to production. We are focused on premium fish species, although our patent-pending technology platform are applicable to other types of meat, such as chicken, pork, and beef.

The third generation is actually happening already. There are companies saying they produce cultivated meat, but some of them do not produce the product end-to-end. They are differentiating by focusing on one or two of the enabling technologies, as well as the product offering. One does medium optimization, for example; another makes the growth factors.

It certainly seems to be a bigger challenge to do everything from the cell line — hard science —all the way to commercialization and branding.

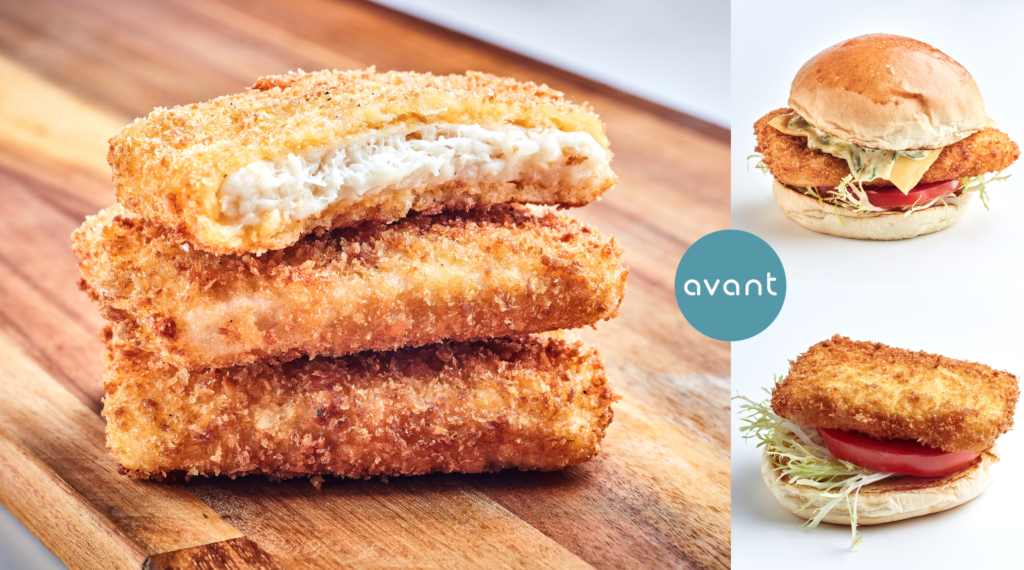

We position ourselves as a tech company more than a product company, unlike Beyond Burger, for example, which is more consumer-facing. But while we hold a number of patents and do a lot of tech, we recognize the need to launch products in the market so people know what the tech can do. It’s always a challenge, the route from patents to commercialization, but we want to have both sides. How we do it is to partner with consumer product companies for co-branding. Examples are Intel and Gore-tex. They do not produce PC. They supply chips to PC makers. Consumers make purchase decisions taking into consideration the key component of the product. We supply our cultivated fish fillets to food companies who further prepare and process them to a pack of frozen fish cutlets in the supermarket.

Singapore recently became the first country to approve cultivated meat for human consumption. What does that mean for Avant Meats? How do you look at regulatory barriers to growth?

The news from Singapore really got people excited. A lot of Southeast Asia markets make reference to Singapore when it comes to regulatory compliance.

We are based in Hong Kong, so our primary market focus is China, but we will have a presence in Singapore as well so we can get closer to the first regulator in the world to approve cultivated meat for human consumption because they have guidelines and experience with the process to review/access/approve the tech. We are already in communication with Singapore’s regulatory body and when we get approval, it will open up quite a bit of the market from us.

We expect China will move quickly as well. We are following the matter.

What impact do you want to have on the environment?

We are working on fish, and in particular more premium species like grouper. We launched a fish fillet burger at a conference in November 2020, and we also launched a Chinese delicacy ingredient called fish maw in 2019. We are also working on a marine protein product that will be B2B.

We started with fish because, unlike land animals, we can rely on catching them directly from the ocean for half of the volume people consume. Between overfishing, pollutants, heavy metals, and micro-plastics, there is a whole new set of problems for the planet, as well as for consumers. By working with fish, we are checking some of our SDG goals. That’s the qualitative answer.

From a quantitative perspective — How do we use energy in protein production? — we are starting to track our use of resources and building that into our system as our product lifecycle moves to pilot scale in 2021.